Machinery and Engineering

At RMD we promote constant technological development. Due to this and the enthusiasm we have to advance daily, we make a determined effort to improve our way of working, which has a direct impact on the optimization of the equipment we use. Our proven track record as recyclers has allowed us to accumulate the necessary knowledge to design our technology. We are currently able to offer a wide range of solutions specifically tailored to recycling processes. The equipment we manufacture is tested under real industrial conditions in our facilities, so we can offer guarantees of its performance and even the possibility of carrying out tests.

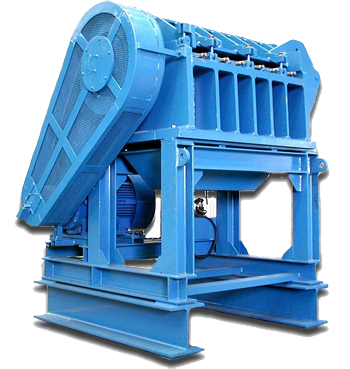

Pre-granulators

RMD pre-granulators and semi-granulators are the ideal complements to primary shredders to reduce the size of materials to grain sizes between 25 and 10 millimetres.

They are also perfect for operating as primary reduction machinery in the recycling of copper and aluminium cables.

The fundamental task carried out by these machines is to prepare the materials so that subsequent granulation processes can be carried out, optimizing yields to the maximum.

- Pre-Granulator Mill

- Semi-Granulator Mill

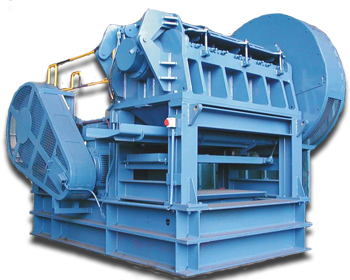

Crushing Equipment

Equipment specifically designed for the preliminary crushing and grinding of large granulometry material.

RMD's primary shredders have been conceived from the experience of daily work in recycling processes and are the best example of our technological development. RMD develops versatile and powerful equipment specially adapted to process all types of tyres, but also electrical and telephone cables, different types of scrap, copper and aluminium profiles and castings, waste...

These machines have a particularly careful geometric design and are very robust, which allows them to work with adequate cutting forces and, therefore, with high yields.

All our equipment operates with highly competitive operating costs that place them at the forefront of the world market.

- 400 MTR 1900 9/10

- 300 MTR 1900 9/10

- 250 MTR 1500 7/8

Rotary Shear

Especially oriented to the primary shredding of tyres, these machines are recommended when high productions are required at a very low cost with few stringent requirements on the output granulometry. Their versatility, however, makes them suitable for reducing a wide variety of waste by simply adapting the cutting format.

Due to its special design, it allows the use of the most suitable blade geometry for each product to obtain optimal performance. Only the blades are exposed to cutting wear, so the reliability of the machine is guaranteed.

- RMD 250-1600/2R

- RMD 200-1200/2R

- RMD 30-600/2R

- RMD 250-1600/2R

- RMD 200-1200/2R English.

Granulators

High-speed equipment for the final stages of the recycling process.

The RMD granulators manage to reduce the material to grain sizes of less than 1 millimetre. They are machines with very low operating costs from which extraordinary productions are obtained in the recycling of soft materials, plastics, and rubbers.

These teams stand out for their capacity and adaptability to different products.

The work system using interchangeable grills makes it possible to adapt the granulometric characteristics of the material obtained to the needs of each specific demand.

- Normal granulator mill (MGN)

- Special granulator mill (MGE).